Milking

“We have not seen teat damage since we have automated robots.”

"We went to Agfest in 2014 with reasonable milk prices, where we gave their Craig the deposit on the spot for 3 milking robots and signed the agreement." - Garry Carpenter, Gunns Plains, Tasmania

Meet Gary Carpenter

Starting back in 1988 with just 28 dairy cows, Garry and Bev Carpenter have had a big ride and an interesting story to share. From converting a beef into a dairy farm, buying 3 milking robots during AgFest, surviving different floodings, to milk +1000 cows on 3 locations on their peak, are just some examples of what you will find in their story. Currently (march 2024) they are married for 45 years, and are milking +380 dairy cows on 7 Lely Astronaut milking robots on 1 location.

How it all started

Garry and Bev started dairying back in 1988 when they converted a beef farm into a dairy farm. They started with 28 cows on a 7 swing-over herringbone. From this moment onwards they purchased in 1991 a neighbor farm and grew to a couple hundred cows. Years later (in 2007) they purchased another neighbor and grew to 600 cows milking on that moment with a 26 double-up herringbone.

Did you know that: the first paycheck from Garry and Bev back in 1988 was $288,-? Back then you could buy a lot of things for that kind of money. – Garry Carpenter

Due to an irrigation scheme they lost 170 acres which was roughly 25% of their farm, back in 2014. That made Garry and Bev look around for more farming ground in the area of Gunns Plains where they saw a pretty piece of land available a few hundred meter around the corner. They signed up for the land without meeting the original owner. Starting with a lease agreement on the farm for a while until the moment they could pay this off. This was roughly 10 years ago (2014) and was also the start for Garry and Bev to work with 3 Lely Astronaut A4 milking robots in one of their hop sheds.

Floodings in Gunns Plains

Gunns Plains is a little town, just 67 meter above sea level and an 15 minute in land from central coast with an beautiful climate, lovely soil, with a river running through the middle of it. The river can also be mentioned as the only downside of Gunns Plains because Garry and Bev are flooded out regularly, roughly every 3 till 5 years.

There was a real severe flooding back in 2016 and a pretty heavy one a couple years ago. In 2016 Garry and Bev were pretty fortunate cause they could have lost heaps of cows because they were locked out of the farm for a couple of days. Also last year they had a flooding where we needed to get cattle out of the river. Unfortunately one cow was lost here.

‘Every year we learn and every flood we learn a bit more.’ – Garry Carpenter.

Buying 3 milking robots at AgFest

The reason of buying a milking robot 10 years ago was because Garry and Bev were coming into a semi-retirement phase of their life and they wanted to enjoy more of their cows, growing grass and the sunset on their farm. My (Garry) body was starting to slow down and we wanted to continue dairy farming in South Riana. Doing this on a beautiful location with an employee doing the main work. This would allow Garry and Bev to come down and work around and with the cows while standing on concrete was not needed anymore.

They had done their research on the milking robots, the different suppliers and they visited a couple of farms with robots before deciding going with Lely. Lely was in that time more than their competitors in R&D and more pasture based oriented which were key factors deciding to go ahead with them, besides the good relationship with the dealer which they already had.

It was around the year 2014 and we (Garry and Bev) went to the AgFest exhibition where Craig Stokes (Lely Center Tasmania) had a stand. On that moment walking in the stand of Craig he had a Lely Astronaut A4 standing there and we paid on the spot the deposit for 3 Lely Astronaut A4 milking robots and signed the agreement.

“We went to Agfest in 2014 with reasonable milk prices and we gave their Craig the deposit on the spot for 3 milking robots and signed the agreement.” – Garry Carpenter

Around 3 years later when we set up the 2nd automated farm, we purchased 4 additional Lely Astronaut A4 milking robots in 2017.

The start-up

“During the start-up phase in 2014 Bev and Jayde (daughter) were working on the other farm with the herringbone in South Riana and we were busy with the start-up of the robots on our farm. When visiting the start-up later in the day they were expecting to meet a team who were exhausted and that the language will not be too pretty. But, they found us (Garry, Craig Stokes and the start-up team) sitting on a bench nipping a whiskey and the cows where doing what they supposed to do. It was a real enjoyable moment.” – Garry Carpenter

“Starting up with milking robots, it was exciting. It was a relief to see the cows being milked on the farm without standing on concrete for 6-7 hours a day. Now I could enjoy our cows all the hours of the day and they just come in all the time. It was an excellent transition.”

Growing grass and seeing his cows full of feed and milk is the most satisfying part of the job for Garry. “Seeing a cow enjoying coming in, being milked and going back to the paddock. That’s the most enjoyment I get out of my work.”

“For my wife Bev that is definitely mating and breeding. She is more into the genetic phase. So together you could say we are a perfect team. Bev was more into the genetics of the cows and breeding the cows and I was more about growing grass and feeding the cows to being milked.”

As a dairy farmer you need to respect what this wonderful animal does for us. She gives back a calf every year, she keeps us alive and pays our bills. We need to treat the cow with a lot of respect, it’s an incredible animal. – Garry Carpenter

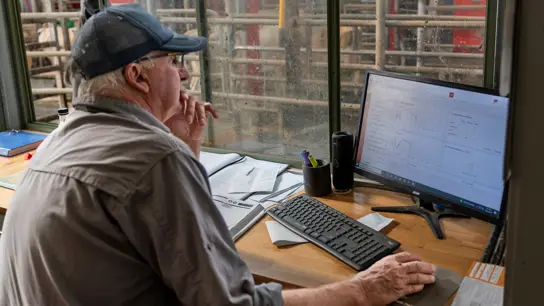

The current dairy

We grow grass (225 hectares) and a fair bit of maize (8 hectares) and will milk 430 up to 440 cows next year. At this moment we feed by-products like carrots and potato-waste through a mixing wagon and feed these to our cows to supplement the grass growth and our silage.

Garry and Bev are doing ABC grazing for 90% of the year. If there is a wet winter they switch back to AB-grazing, cut back their milking frequency to safe pasture. Grazing and robotic milking, this was the biggest concern of Garry how this should work in practice. Even when people tried to explain this on a piece of paper he could not get his head around. In the end it wasn’t worth the worry at all. Garry mentioned that in reality, grazing is not different than with conventional milking.

We have two calving patterns in spring and autumn. This period of the year is the specialty of my wife, the backbone of our dairy.

The backbone of our company

And with the name Bev we touch the backbone of the dairy side of the company. When we started with 28 cows, she was right on the farm while I was away doing roadworks. A big part of the dairy industry was based on her. She was used doing the breeding, calf rearing, following different pasture courses. She loves her Holstein cows and went to a big number of shows in the past. With quite some success.

The wake-up call

Our plan was originally to have three milking robot farms, roughly 5 minutes apart from each other in Gunns Plains, with share farmers on it. Doing this with milking robots on every farm and we could give everybody a weekend off regularly. On our peak we had 3 farms: one with 3 milking robots, one with 4 milking robots and one with a 26 double-up herringbone milking a total of +1000 cows on 3 farms.

But then on the age of 61 a wake-up call was there. Garry got a heart disease and they were thinking: ‘what are we doing it all for?’. They decided to go back to 1 farm on 1 location, trying to enjoy life a bit better. So Garry and Bev shut down 2 farms, one with 3 milking robots, one with a 26 double-up herringbone and combined them to the farm which we have today, with 7 milking robots.

Trying to enjoy life a little bit better

After the wake-up call the idea was trying to enjoy life a little bit better. Then, during the interview Bev told Garry to tell the truth. This is, that Garry is a busy man still, but with a variety of roles. Gary is the past chairman of Holstein Australia where he is in his 11th year and most likely in his last term. Next to this Garry is the current president for the NWFL footy in Tasmania and still has a role as a counselor on central coast councils.

But, Gary is enjoying his different roles and learned a lot from his time as a past chairman of Holstein Australia. He mentioned this has been a good thing for him to learn from and met a lot of lovely people from around the world and share the passion of breeding good cattle.

Did you know that Garry was a real sportsmen with a footie career? He played in 3 premierships and he has life membership in one of the clubs he played in.

My message to fellow farmers about automatic milking

Both for the farmer and the cows the system is incredible. “The longevity of a cow in automatic milking is unlimited. I reckon you can let cows in automatic milking for 10-12 lactations consistently.”

Also for the farm owners lifestyle and health wise the system is of a high benefit. No pressure on legs, shoulders and back anymore which the benefits of it are unmeasurable. “You can milk with AMS till you are 100 years old, because you are not psychically wearing your body parts out. That is worth a fortune for people”.

“We have not seen teat damage since we have automated robots.” – Garry Carpenter

Our customers